GMI was a very professional business to work with. Shipping was quick and easy. Technical Support was quick to respond. I would highly recommend GMI for all your laboratory equipment needs.

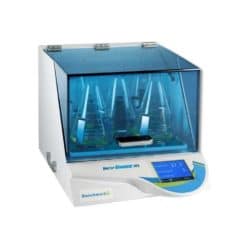

Jeio Tech Lab Companion ISS-7200 / ISS-7200R Incubated Shaker

$11,367.00 – $12,467.00

18-Month Factory Warranty Included

Not sure which configuration is right for your application? Schedule a free consultation with our technical consultants today!

Schedule a consultationProduct Description

Multi-Stackable type

Maximal space-saving multi-stackable model

- Maximum triple-stacked for space saving.

- Strong DD motor for large-capacity.

- 120V, 60Hz

Structural Functional Features

- Large-capacity triple stackable incubated shaker.

- Up to 80°C, 400rpm enables experimental conditions for various applications.

- Three operating modes: Temperature & Shaking, Temperature, or Shaking.

- Shaking structure with minimized vibration.

- Convenient to change samples with glide-up door.

- Stable shaking of high-load samples. (patent registered: 10-1678160)

Use Convenience Features

- Accurate rpm and temperature control through temperature autotuning / microprocessor PID and calibration.

- Monitor via mobile app anytime, anywhere with LC Connected.

(mobile monitoring system) (when purchased LC GreenBox) - Countdown timer (999 hours 59 minutes) of shaking operation.

- Intuitive operation with color touch display.

- High brightness / low-power LED illumination makes it easy to observe inside.

- Spill drain port for internal cleanliness and easy maintenance.

- Stand with adjustable feet to ensure a level installation, and retractable casters to allow positioning prior to installation.

(Retractable Foot Caster)

Outstanding Safety

- Electronic over temperature protection system.

(A-OT, advanced over temperature limiter)

Independent precision temperature sensor and controller provides more secure and reliable over temperature protection. - Conventional over-temperature protection system.

(B-OT, backup over temperature limiter)

A backup device against electronic system failure, mechanically preventing over temperature even when there are electronic errors. - Soft start and stop shaking function.

- Malfunction prevented by controller lock function.

- Displays all information such as device operation and error occurrence.

- Overcurrent protection device restricts operation when objects are caught inside the system and shaking is not possible.

Smart Self-diagnosis

- Real-time self-diagnostics to check equipment for abnormal conditions.

- Alarm is generated by monitoring difference between actual rpm/temperature and set rpm/temperature.

- Automatic rpm adjustment when device instability occurs.

(high rpm, overload, weight imbalance, etc.) - Detects abnormal conditions relating to the platform on which the sample is placed and stops the operation.

- Automatic restart as it was operated after power recovery.

Technical Specifications

| Temperature | |

|---|---|

| Range (℃ / ℉) | Amb. +10 to 80 / Amb. +18 to 176 | Amb. -20 (Min. 4) to 80 / Amb. -36 (Min. 7.2) to 176 |

| Fluctuation at 37℃ (±℃ / ℉) in flask | 0.1 / 0.18 |

| Variation at 37℃ (±℃ / ℉) in flask | 0.6 / 1.08 | 0.5 / 0.90 |

| Refrigerator (Hp) | – | 1/6 |

| Shaking system | |

| Motion type | Orbital |

| Speed range (rpm) | 30 to 300 (stackable : 30 to 200) |

| Max. speed per permissible load (rpm) | 1 unit only 300 (max. 20 kg / 44.1 Ibs)Stacked units 200 (max. 15 kg / 33.1 Ibs) 150 (max. 20 kg / 44.1 Ibs) |

| Amplitude size (mm / inch, dia.) | 50.8 / 2 |

| Speed stability2) (rpm, %) | ±1 |

| Timer (count-down) | 999 hr 59 min. |

| Dimension (1 unit) | |

| Chamber volume (L / cu ft) | 198 / 7.0 |

| Platform (W x D, mm / inch) | 755 x 520 / 29.7 x 20.5 |

| Interior (W x D x H, mm / inch) | 809 x 624 x 393 / 31.9 x 24.6 x 15.5 |

| Exterior (W x D x H, mm / inch) | 1 unit ; 1307 x 996 x 755 / 51.5 x 39.2 x 29.7 1 unit+stand-I or 2 units stacked ; 1307 x 996 x 1355 / 51.5 x 39.2 x 53.3 2 units+stand-II stacked ; 1307 x 996 x 1655 / 51.5 x 39.2 x 65.2 3 units stacked ; 1307 x 996 x 1955 / 51.5 x 39.2 x 77.0 |

| Net weight (Kg / lbs) | 300 / 661.4 | 320 / 705.5 |

| Electrical requirements (120V, A) | 60Hz, 7.1 | 60Hz, 10 |

| Cat. No. | AAH239115U | AAH239215U |

1) The temperature control range of the ISS-7100 and ISS-7200 models are from 10°C above the ambient temperature of the equipment. (15°C to 40°C) to 80°C The temperature control range of the ISS-7100R and ISS-7200R models are from 20°C below the ambient temperature (18°C to 35°C) of the device to 80°C. (However, the lowest control temperature is 4°C)

2) Actual rpm allowable error for set rpm is 1rpm if setting is less than 100rpm, ±1% if setting is higher than 100rpm.

Technical Specifications

| Temperature | |

|---|---|

| Range (℃ / ℉) | Amb. +10 to 80 / Amb. +18 to 176 | Amb. -20 (Min. 4) to 80 / Amb. -36 (Min. 7.2) to 176 |

| Fluctuation at 37℃ (±℃ / ℉) in flask | 0.1 / 0.18 |

| Variation at 37℃ (±℃ / ℉) in flask | 0.6 / 1.08 | 0.5 / 0.90 |

| Refrigerator (Hp) | – | 1/6 |

| Shaking system | |

| Motion type | Orbital |

| Speed range (rpm) | 30 to 300 (stackable : 30 to 200) |

| Max. speed per permissible load (rpm) | 1 unit only 300 (max. 20 kg / 44.1 Ibs)Stacked units 200 (max. 15 kg / 33.1 Ibs) 150 (max. 20 kg / 44.1 Ibs) |

| Amplitude size (mm / inch, dia.) | 50.8 / 2 |

| Speed stability2) (rpm, %) | ±1 |

| Timer (count-down) | 999 hr 59 min. |

| Dimension (1 unit) | |

| Chamber volume (L / cu ft) | 198 / 7.0 |

| Platform (W x D, mm / inch) | 755 x 520 / 29.7 x 20.5 |

| Interior (W x D x H, mm / inch) | 809 x 624 x 393 / 31.9 x 24.6 x 15.5 |

| Exterior (W x D x H, mm / inch) | 1 unit ; 1307 x 996 x 755 / 51.5 x 39.2 x 29.7 1 unit+stand-I or 2 units stacked ; 1307 x 996 x 1355 / 51.5 x 39.2 x 53.3 2 units+stand-II stacked ; 1307 x 996 x 1655 / 51.5 x 39.2 x 65.2 3 units stacked ; 1307 x 996 x 1955 / 51.5 x 39.2 x 77.0 |

| Net weight (Kg / lbs) | 300 / 661.4 | 320 / 705.5 |

| Electrical requirements (120V, A) | 60Hz, 7.1 | 60Hz, 10 |

| Cat. No. | AAH239115U | AAH239215U |

1) The temperature control range of the ISS-7100 and ISS-7200 models are from 10°C above the ambient temperature of the equipment. (15°C to 40°C) to 80°C The temperature control range of the ISS-7100R and ISS-7200R models are from 20°C below the ambient temperature (18°C to 35°C) of the device to 80°C. (However, the lowest control temperature is 4°C)

2) Actual rpm allowable error for set rpm is 1rpm if setting is less than 100rpm, ±1% if setting is higher than 100rpm.

Replacement Parts & Accessories

To view available parts for this instrument and instruments like it, click here.

Our parts and accessories inventory is constantly changing. Don't see what you're looking for? Give us a call, we'll be happy to help.

Service

Service Agreements |

Silver |

Gold |

First Class Ship & Fix |

Economy Ship & Fix |

| Preventative Maintenance Visit | 1 Preventative Maintenance Visit per Year | 1 Preventative Maintenance Visit per Year | ||

| Parts Covered |  |

|

||

| Labor Covered |  |

|

|

|

| Unlimited Remote Tech Support |  |

|

|

|

| Depot Repair |  |

|

||

| Depot Preventative Maintenance |  |

Reviews