Perfect Environmental Simulation

Memmert environmental test chambers provide rapid and energy-saving temperature changes with precise control and fast recovery times.

Environmental test chambers are used to simulate environments for controlled testing purposes. These chambers see use in a wide variety of labs from pharmaceutical, biological, product testing, botany, and other labs. Precision control over temperature and humidity allow for accurate simulation of a large spectrum of environments.

Memmert produces industry-leading environmental test chambers that feature unique stainless steel that’s scratch resistant, hygienic, robust, and ever-lasting. We offer environmental test chambers in all sorts of shapes, sizes, and dimensions so you’re sure to find one that fits your space and requirements.

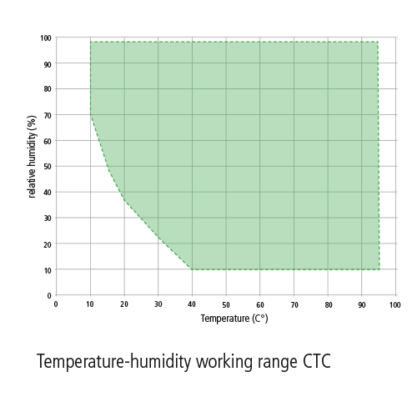

Perfect climatic test chamber with combined humidity and temperature control, -42C to 190C without RH, and +10C up to +95C with RH.

Scratch resistant, hygienic and durable.

A limited 2 year warranty is included with the option to purchase an extra year.

Memmert environmental test chambers provide rapid and energy-saving temperature changes with precise control and fast recovery times.

The chambers 3-layer insulation system prevents moisture penetration of the insulation material for permanent insulation capacity and energy efficiency.

Chambers feature an electronically controlled active humidification and dehumidification with an automatic defrosting system for uninterrupted and continuous operation.

A condensation-free permanent operation is possible within the respective temperature-humidity range.

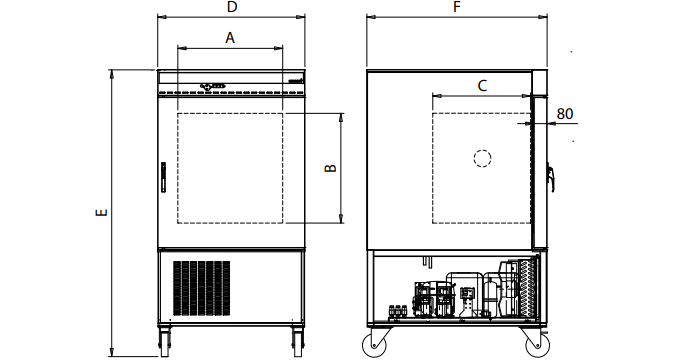

| Chamber width A* [mm] | 640 | ||

| Chamber height B* [mm] | 670 | ||

| Chamber depth C* [mm] | 597 | ||

| Appliance width D* [mm] | 898 | ||

| Appliance depth F* [mm] | 1100 | ||

| Appliance height E* [mm] | 1730 | ||

| Chamber volume [liter] | 256 | ||

| Performance [W] | 7000 | ||

| max. number of sliding grates | 6 | ||

| max. load per sliding grate [kg] | 25 | ||

| max. load per appliance [kg] | 100 | ||

| Temperatures min/max. | –42 ºC/+190 ºC | ||

| Adjustment precision | –42 °C – 100 °C: 0,1 °C100 °C – 190 °C: 0,5 °C | ||

| Monitoring | –50 ºC … +200 ºC | ||

|

Refrigerant used

|

Type | R449A | |

| GWP | 1397 | ||

| Filling weight | 1.8 kg | ||

| CO2 equivalent | 2.51 t | ||

| Humidity | 10-98% rh | ||

| Air circulation in chamber | ≤ 1200 m³/h | ||

| Electrical equipment | |||

| Operating voltage | 3N~400 V | ||

| Current consumption | 10,6 A | ||

| Safety class | 1 (acc. to EN 61010) | ||

| Degree of protection | IP 20 (EN 60529) | ||

| Interference-suppressed | class B acc. to EN 55011 | ||

| Fuses | 250 V/F 15 A | ||

| * See Figure | |||

| Weight | 1600 oz |

|---|---|

| Dimensions | 40 × 48 × 48 in |

| Model | CTC256, TTC256 |