1-Year Full Standard Factory Warranty

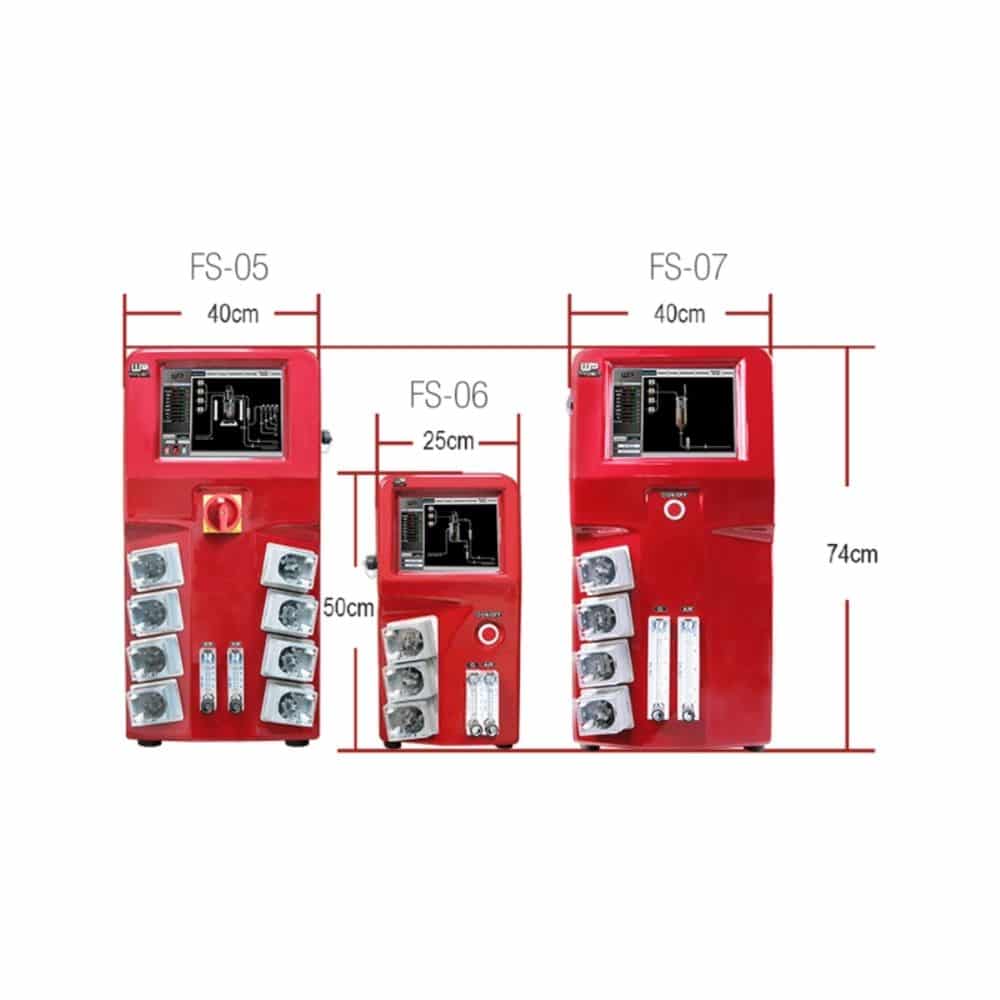

Winpact One Fermentation System, FS-06 series

Not sure which configuration is right for your application? Schedule a free consultation with our technical consultants today!

Schedule a consultationProduct Description

The Winpact One System is the most versatile, price and space saving fermentation system available from our Winpact fermentation product line.

Winpact One is compact in size, but still provides all the necessary tools as a standard instrument. The duo heating system allows you to choose any vessel type up to 10L for any application needs. The optional expansion module allows you to add additional devices to enhance the capability of the system. All necessities such as temperature, anti-foam, pH and DO probe are all included in the standard package.

Features

- 8″ Color touch-screen interface

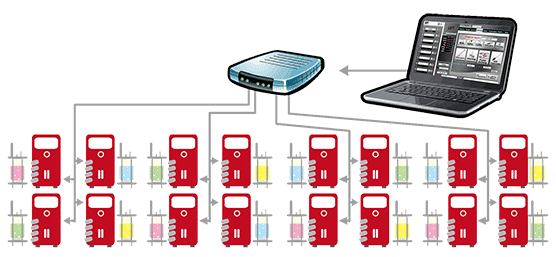

- Remote software control through Ethernet, up to 16 systems / PC

- Data export through USB port

- Up to 59,994 programs for different kinds of condition

- Footprint: W x L = 9.84″ x 20.08″ (250 mm x 510 mm), Height: 19.69″ (500 mm)

- Duo heating system, thermostat and dry heating combined in one

- Most versatile and compact system on the market ((WxLxH) 250x510x500mm)

- Interchangeable 5 types of autoclavable glass vessel

- Control up to 16 systems from a single interface

- Compatible with microbial and cell culture applications

- Intuitive user interface for self-explanatory time with multi-language support

- Ethernet communication with Winpact SCADA software, and IP addressing

- Expansion module available for system upgrade for optional devices

1. Single wall dish bottom vessel, 1L

2. Double jacketed dish bottom vessel, 3L

3. Single wall air lifter vessel, 5L

4. Double jacketed air lifter vessel, 5L

5. Single wall dish bottom vessel with heating blanket, 5L

6. Single wall plain bottom vessel with heating base unit, 10L

7. Solid State, 5L

| Weight | 1600 oz |

|---|---|

| Dimensions | 40 × 48 × 48 in |

| Instrument Type |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.