HPLC, New Laboratory Equipment

Troubleshooting Guide for HPLC Auto-Samplers

High performance liquid Chromatography (HPLC) is a powerful analytical technique used in various industries, such as pharmaceuticals, environmental analysis, and food testing. The auto-sampler is central to an efficient HPLC system, which injects samples into the chromatograph for analysis. However, like any complex instrument, auto-samplers can encounter issues that affect their performance. This blog post will explore common troubleshooting steps for HPLC auto-samplers and how the GMI Service Team can provide expert assistance.

Common Issues and Troubleshooting Steps

- Injection Errors: If your auto-sampler is experiencing injection errors, such as partial injections or air bubbles in the sample loop, check the injection needle for blockages or damage. Clean or replace the needle as needed, and ensure proper sample preparation techniques are followed to prevent air bubbles.

- Sample Contamination: Sample contamination can lead to inaccurate results and instrument downtime. Check the sample vials, septa, and injection ports for cleanliness. Use high-quality vials and septa to minimize contamination risks.

- Leakage: Auto-samplers may experience leaks at various points, including the injection valve or tubing connections. Inspect all fittings and seals for signs of leakage and tighten or replace components as necessary. Regular maintenance and inspection can prevent significant leaks.

- Poor Reproducibility: Inconsistent injection volumes or peak shapes can indicate issues with the autosampler’s calibration or flow settings. Calibrate the autosampler according to manufacturer guidelines and ensure proper flow rates for optimal performance.

- Error Codes: Auto-samplers often display error codes that indicate specific issues. For troubleshooting guidance related to error codes, refer to the instrument manual. In case of persistent errors, contact the manufacturer or a qualified service provider.

How the GMI Service Team Can Help

At GMI, we understand the critical role of HPLC auto-samplers in your analytical workflows. Our experienced Service Team is dedicated to ensuring the optimal performance and reliability of your instruments. Here’s how we can assist:

- Preventive Maintenance: Schedule regular maintenance checks to identify and address potential issues before they escalate. Our technicians perform comprehensive inspections and calibration to keep your auto-sampler in top condition.

- Troubleshooting Expertise: If you encounter complex issues or error codes that require specialized knowledge, our Service Team is equipped with the expertise to diagnose and resolve problems efficiently. We follow industry best practices and use genuine replacement parts for repairs.

- Calibration and Optimization: Our calibration and optimization services ensure accurate and reproducible results. We fine-tune your auto-sampler settings to match your specific applications and analytical requirements.

- Emergency Support: In case of unexpected breakdowns or urgent service needs, our team provides prompt response and on-site repairs to minimize downtime and keep your operations running smoothly.

- Training and Consultation: We offer training and technical consultations to enhance instrument performance and user proficiency and equip your staff with the skills and knowledge to operate and maintain auto-samplers effectively.

Don’t let auto-sampler issues disrupt your analytical processes. Trust the GMI Service Team to deliver reliable solutions and exceptional support for your HPLC instrumentation. Contact us today to learn more about our services and how we can optimize your laboratory workflows.

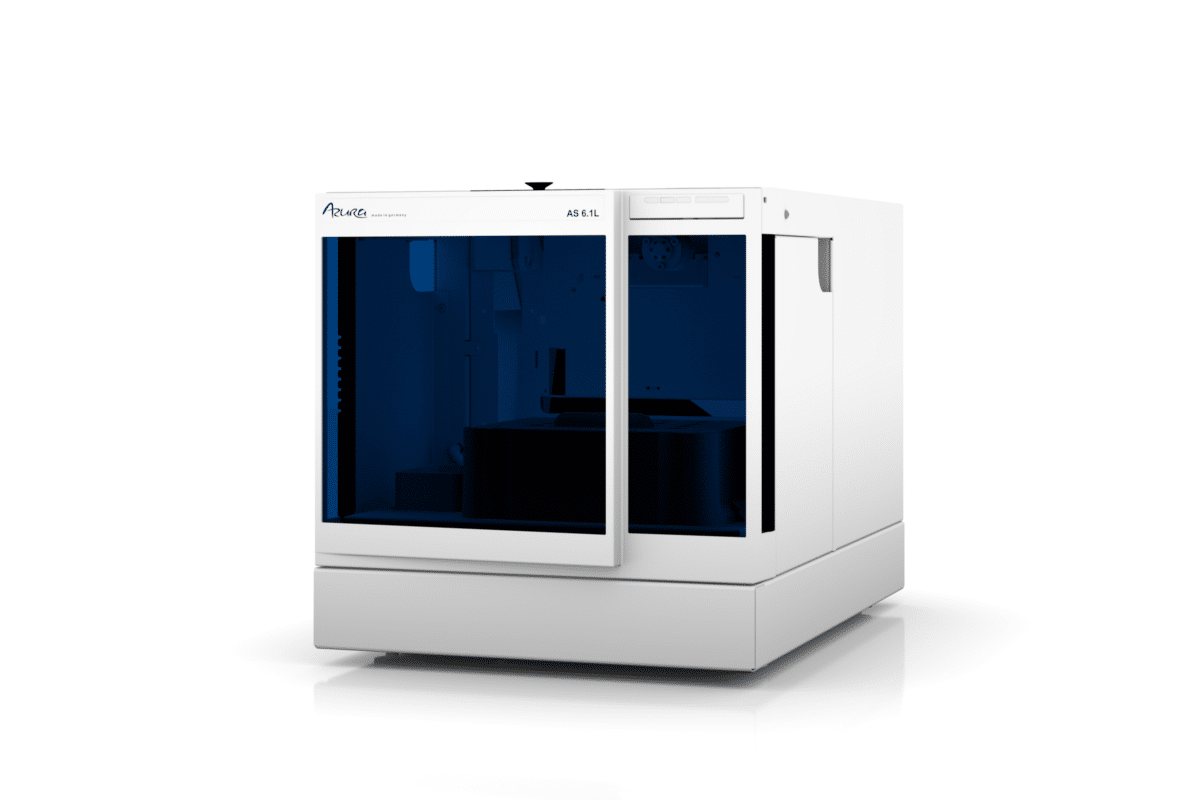

GMI repair & service shop knauer autosamplers